Industrial Titanium & Steel Cathodes

Titanium and Steel Clad Copper Cathode and MMO Anode Supplier. Complete Electrode Solutions for Electrolysis, Chlor-Alkali & Green Hydrogen Systems

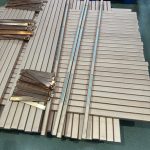

- Titanium Clad Copper Bars

- Bus Bars, Hangers, Blanks, Ears

- Rapid Production to Custom Designs

- Free Quick Quote

Titanium Cathodes & Anodes

- Titanium Clad Copper

- Bus Bars, Hangers

- Rapid Production

- Custom Designs

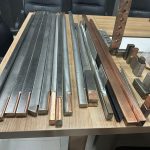

Titanium Clad Copper

Titanium clad copper bar. Combining excellent conductivity of copper and high corrosion-resistance of titanium:

Precision cutting and welding

Controlled straightness and flatness tolerances

Custom bar sizes and configurations

Steel-clad copper options available

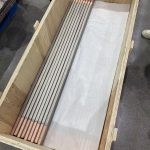

Titanium Clad Copper Bus Bars. Low-resistance, high-current distribution between rectifiers, anodes, and cathodes for efficient, uniform flow in demanding electrolytic environments:

High current density with low voltage drop

Heavy-duty mechanical strength

Corrosion-resistant for aggressive electrolytes and humidity

Precision fabrication, bending, drilling, and finishing

Ensures stable current distribution, reduced energy loss, and long-term reliability in continuous electrochemical operations.

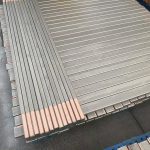

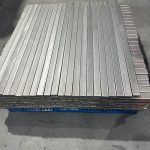

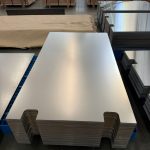

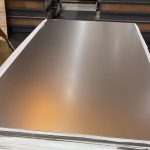

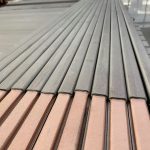

Cathodes Sheets

Used in electrowinning, electrorefining, chlor-alkali processing, electroplating, and metal recovery. Cathodes offer excellent corrosion resistance, dimensional stability, and long service life in aggressive electrolytic environments:

- Automated production line.

- Precise welding, slotting and drilling.

- Tight flatness tolerance for efficient performance.

- Custom Design.

Titanium MMO Anodes

Mixed metal oxide (MMO) anode products with advanced coatings including Ruthenium, Iridium, and platinum, engineered for high electrochemical activity, low overpotential, and excellent durability. Optimised for demanding electrochemical processes, these anodes offer superior corrosion resistance, stable performance, and long service life across a wide range of electrolytes and current densities.

Ruthenium Plated

RuO2+IrO2+Pt+X

Base: Ti (Gr1, Gr2)

High Corrosion Resistance

Cost-effective

Iridium Plated

IrO2+Ta2O5+X

Base: Ti (Gr1, Gr2)

Long-Term Durability

High Stability

Platinum Plated

Pt Purity 99%

Base: Ti (Gr1, Gr2)

Increased Electrocatalysis

High Durability

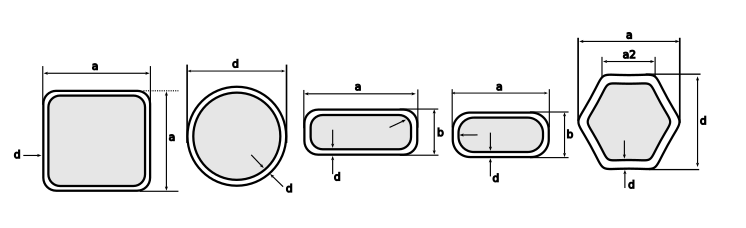

Titanium Anode

Titanium (Gr1, Gr2)

- Rectangular

- Round / Spiral

- Custom Designs

Industry News & Highlights

Electrowinning vs Electrorefining: Key Differences in Copper Production

Discover the key differences between electrowinning and electrorefining in copper production.

How Copper Electrowinning Works: Process Overview and Equipment

Learn about the copper electrowinning process and the essential equipment involved in extracting high-purity copper from leach solutions.

Environmental Benefits of Using Titanium Cathodes in Industrial Processes

Discover the eco-friendly advantages of titanium cathodes in industrial processes, from energy savings to reduced waste.

Scaling Electrochemical Systems with Titanium Cathode Technology

Discover how titanium cathodes are transforming electrochemical systems for scalability and efficiency.

Thermal and Electrical Properties of Titanium in Cathodic Applications

Explore the thermal and electrical properties of titanium and its significance in cathodic applications.

Titanium Cathodes in Wastewater Treatment Electrochemical Processes

Explore how titanium cathodes enhance electrochemical processes in wastewater treatment, offering durability and efficiency.

Standard Anode is a subsidiary of Standard Titanium Co. Ltd, a leading manufacturer of titanium products. Standard Anode is dedicated to the development and production of electrode products including MMO Anodes, Titanium Clad Copper and Cathodes.

Our products are precision engineered to ensure durability over long lifetimes. Our automatic production line of copper cladding and cathode manufacture allows us to produce to custom specifications and to low tolerances. Our products are durable, reliable and are high performance.

Standard Anode is a leading supplier of products for Water Treatment, Electrowinning, Electroplating, and PCB Production.

- No12, Jinye 1st Rd, Yongwei Times Center, Yanta District, Xi’an, Shaanxi, China, 710076

- +86 (0)29 8116 2926

- Timing: 9am -8pm

- info@standardanode.com